Materiality 2

Product safety and security through comprehensive quality control

Basic policy

NITORI Group always has the customer’s perspective and recognizes its social responsibility to contribute to safe and secure lives of customers, not to mention offering products with stable quality at affordable prices. We work to improve quality and ensure safety at all times, so that customers can use our products safely and with peace of mind.

Pursuing correct manufacturing and responsible procurement

NITORI Group considers affordability, quality, and coordination as the most important factors in manufacturing. Quality means that measures are taken to ensure appropriate functions and product safety, and that products are made through the correct manufacturing process (in terms of sincerity, respect for human rights, compliance, occupational safety, environmental protection, etc.). We aim for sustainable growth throughout the entire supply chain by explaining to and sharing with not only our own factories but also suppliers, who are our partners in achieving the mission, the importance of being environmentally conscious and fulfilling social responsibilities, as well as our ideas to create a culture of product safety.

Development of Environmentally Conscious Products

Nitori believe that working to solve global environmental issues caused by chemical substances contained in our products will lead to the development of sustainable social and economic activities.

We are working with its suppliers to develop products that reduce the use of hazardous substances that affect the environment.

Content information of specified chemical substances based on J-Moss

Since July 1, 2006, the Law for Promotion of Effective Utilization of Resources requires by law that products manufactured, imported, and sold must be labeled as containing specified chemical substances as stipulated in JIS C 0950 (J-Moss).

The purpose is to provide content information to recycling companies as well by labeling items for which a recycling system has been established.

Nitori does not manufacture, import, or sell any products that contain specified chemical substances exceeding the standard values in parts other than those exempted by this law.

Content information of specified chemical substances based on J-Moss![]()

Initiatives of our own factories overseas

Initiatives to ensure comprehensive quality control and

improve work environment in the Group’s own factories

NITORI Group is a manufacturer that has its own factories at domestic and overseas locations. Each factory commits to quality control in the manufacturing process. For example, the factory in Vietnam (NITORI FURNITURE) conducts voluntary audits mainly on quality control, led by an independent local department that specializes in quality control. Employees also participate in “Product Safety and After* Sales Service Reduction Meetings,” where employees gather customer’s voice to make improvements and reforms, and Nitori World Circle (NWC) activities (NITORI Group’s unique small group activities where employees identify issues from everyday tasks and make improvements and reforms). To improve quality and productivity, they carry out tasks every day with high motivation. In addition, departments specialized in factory control monitor occupational safety and attendance, based on NITORI Group’s belief that creation and improvement of work environment leads to stable quality. The purpose of their strict checks includes ensuring that there are no risks that may lead to accidents and that employees are taking sufficient break times. Furthermore, free meals are served in the factory cafeterias, and the filling, tasty meals are well received by our employees. Our own factories create employment in local areas and contribute to the development of local communities. The factories’ initiatives to ensure comprehensive quality control and improvement of work environment are and taken advantage of, as precious know-how, in building partnerships with overseas suppliers.

*Troubles raised by customers

Initiatives of our own factories overseas to address environmental and social issues

Approximately 9,900 employees (of which 81% are women) work at our overseas factories. NITORI Group creates local employment and contributes to the development of local communities. The factory promotes automation and labor saving in the production lines for furniture and other large products. New machines, equipment and tools are constantly being installed, such as the “vacuum lift” (*picture on the right), which enables safe operation with less human power, even for large products. As a result, not only does this improve production efficiency, but also creates a comfortable working environment at work sites where there is a high ratio of female workers.

Initiatives with Suppliers

Comprehensive quality control through the United

Collaboration System with overseas suppliers

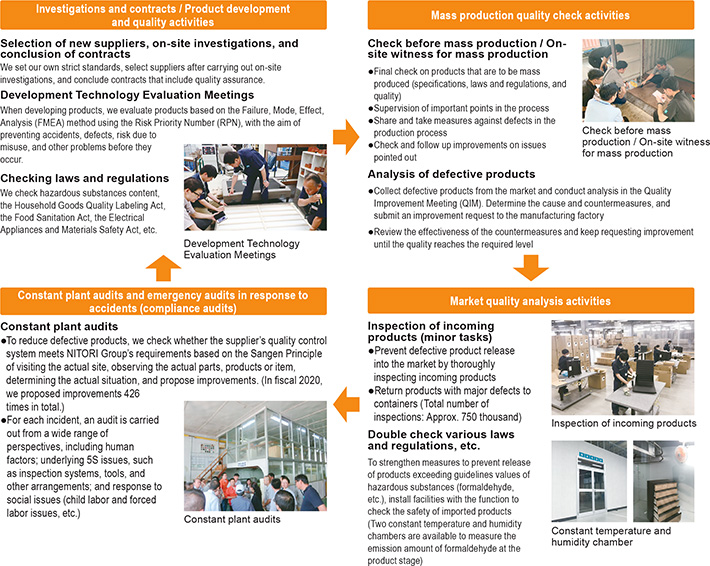

We not only ensure compliance in relation to suppliers, who are our partners in achieving the mission, but also share with them ideas and management methods to build a culture of product safety. In the following processes, strict standards have been set and PDCA cycles implemented. We establish true partnerships with suppliers and aim for sustainable growth together.