Materiality 3

Promotion of

environmentally conscious business

Basic policy

To prevent its business expansion from increasing environmental impact not only within the Company but also throughout the entire supply chain including suppliers, NITORI Group strives to be environmentally conscious at all times by saving resources and energy. In addition, we aim to promote initiatives that conserve and improve the environment through business and to contribute to the creation of a better environment.

- Related data[

460KB]

460KB]

- Greenhouse gas emissions from NITORI Group

- Energy use (gas, kerosene, gasoline, diesel oil, and electricity) by NITORI Group

- Amount of waste from NITORI Group’s domestic operations

- Amount of water used

Development of Environmentally Conscious Products

Nitori believe that working to solve global environmental issues caused by chemical substances contained in

our products will lead to the development of sustainable social and economic activities.

We are working with its suppliers to develop products that reduce the use of hazardous substances that affect

the environment.

Content information of specified chemical substances based on J-Moss

Since July 1, 2006, the Law for Promotion of Effective Utilization of Resources requires by law that products manufactured, imported, and sold must be labeled as containing specified chemical substances as stipulated in JIS C 0950 (J-Moss).

The purpose is to provide content information to recycling companies as well by labeling items

for which a recycling system has been established.

Nitori does not manufacture, import, or sell any

products that contain specified chemical substances exceeding the standard values in parts other than those

exempted by this law.

Content information of specified

chemical substances based on J-Moss![]()

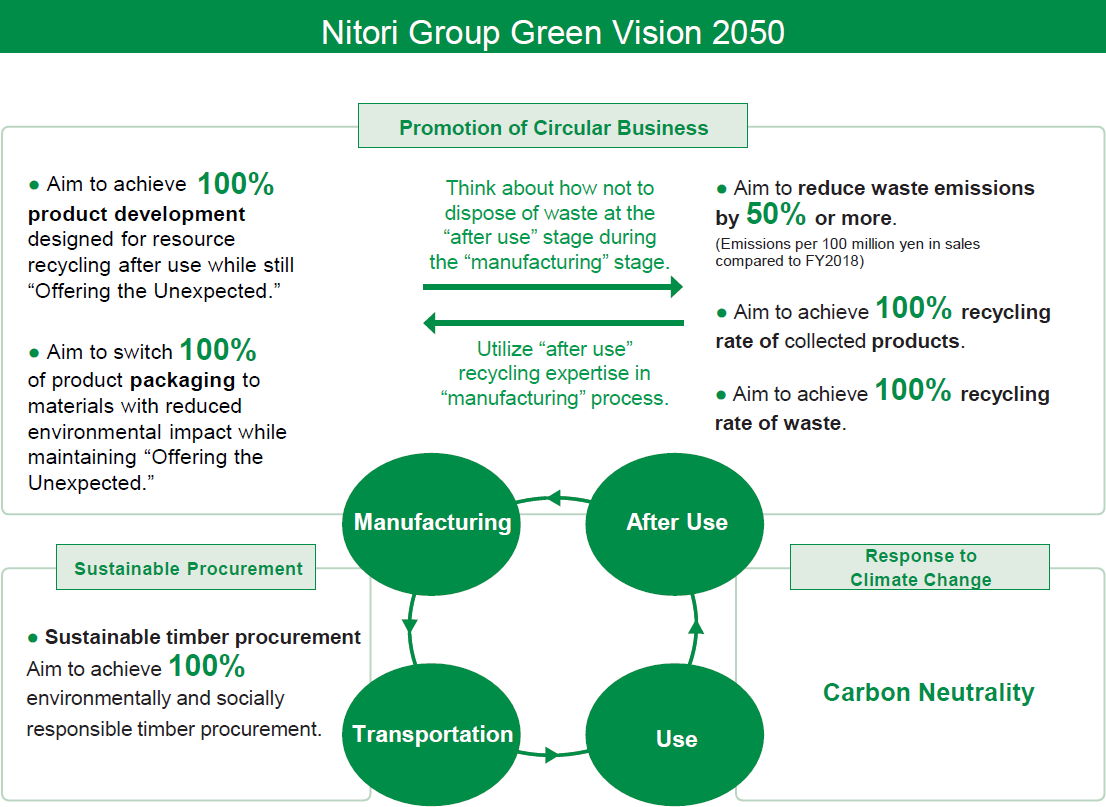

NITORI Group Green Vision 2050

The “Nitori Group Green Vision 2050,” formulated and disclosed in August 2024, is a set of goals for 2050

that aim to realize environmental friendliness and sustainable “enriched homes” by making the most of the

NitoriGroup’s unique circular business model. This vision is based on three themes: 1) Promotion of Circular

Business,

2) Sustainable Procurement, and 3) Response to Climate Change. The entire Nitori Group will work

together to promote efforts to achieve these goals.

The Nitori Group Aims to Realize Sustainable “Enriched Homes.”

The Nitori Group aims to achieve the “NitoriGroup Green Vision 2050” to realize sustainable “enriched

homes.”

Because we are engaged in business using limited resources, we promote circular business by

considering even “after use.” We also strive to enable our customers to experience a reduction in their

environmental impact through shopping at the Nitori Group. At the same time, we will maintain the “Offering

the Unexpected” price and quality that everyone can easily afford.

We are committed to ensuring that the

next generation can enjoy an affluent lifestyle, and that this lifestyle is sustainable. The Nitori Group is

earnestly working to realize the “NitoriGroup Green Vision 2050” in the hope that the “enriched homes” will

continue not only for our generation but for future generations as well.

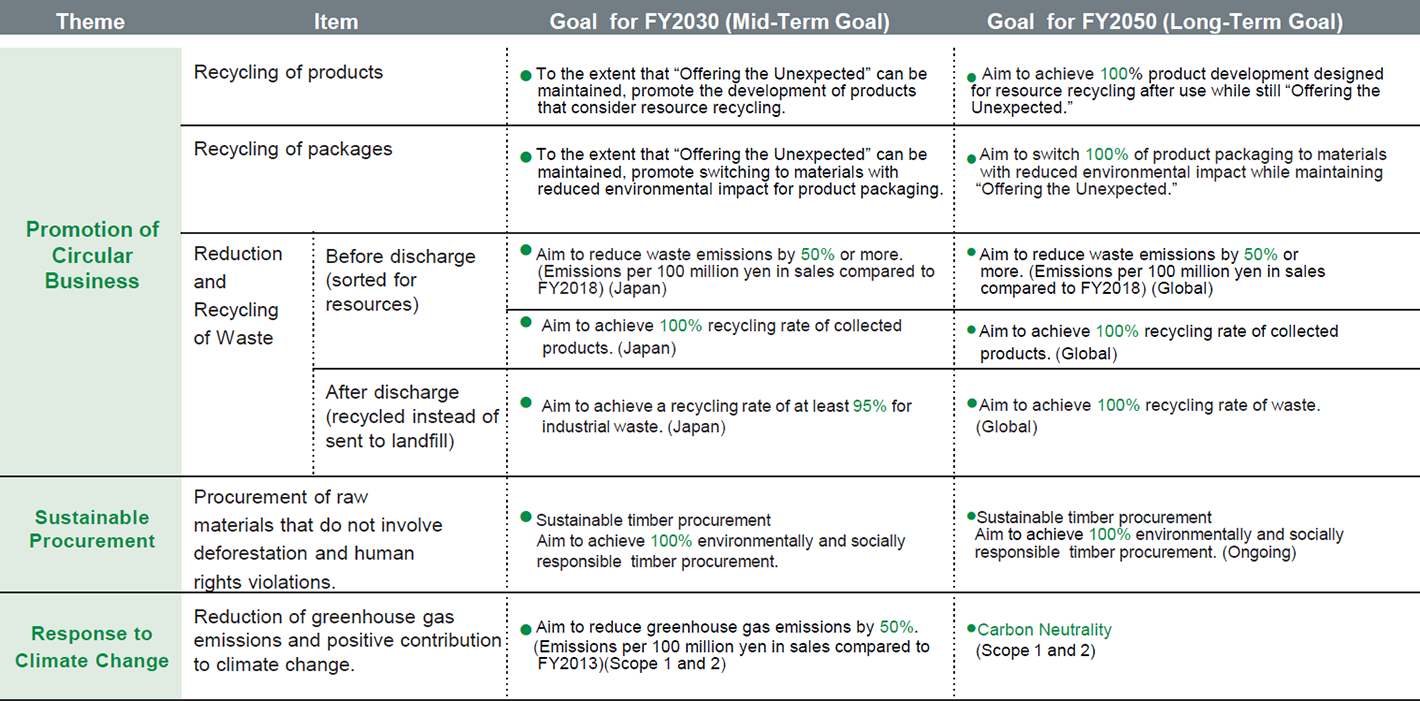

Overview of the NitoriGroup Green Vision 2050(Medium-and Long-Term Vision)

The NitoriGroup Green Vision 2050 is the NitoriGroup’s medium-and long-term environmental goals.

For each

theme, we have set medium-term goals for FY2030 and long-term goals for FY2050.

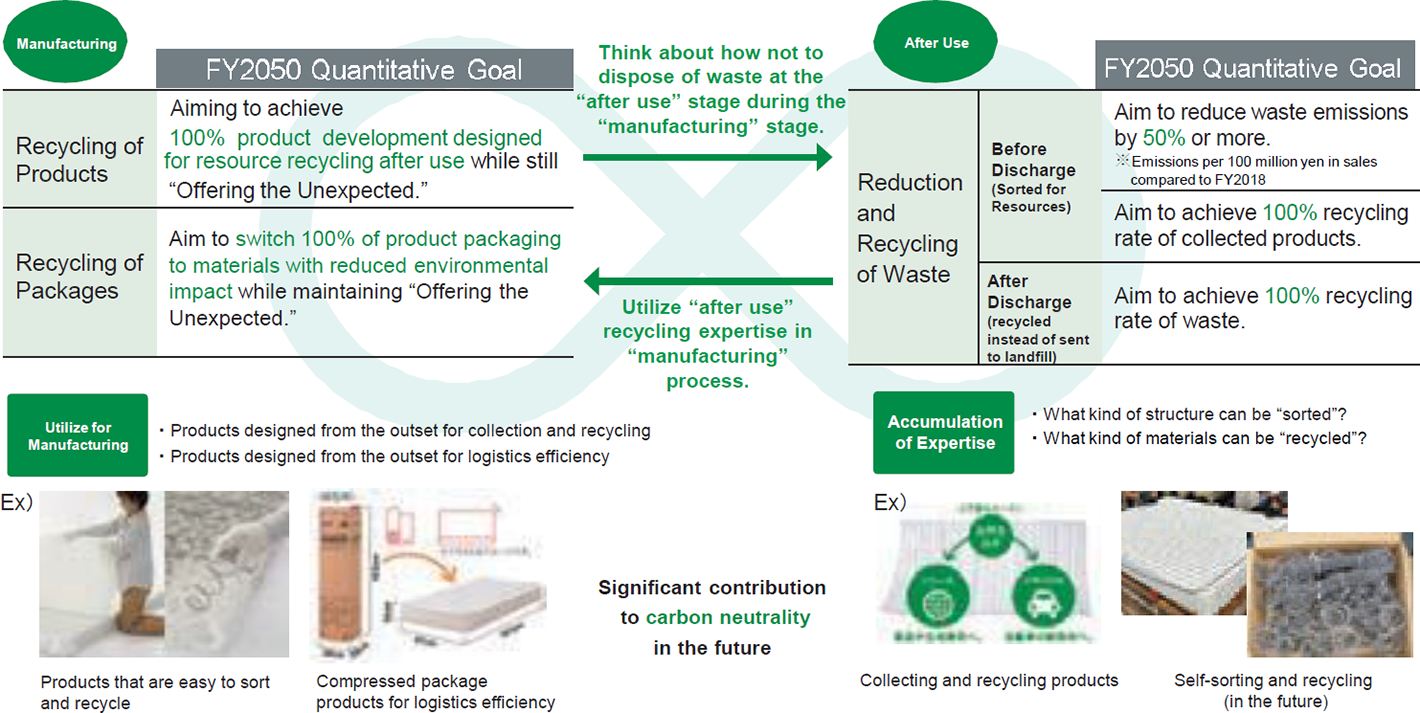

Promotion of Circular Business

Policy

NITORI Group recognizes the finite nature of resources and strives to reduce the amounts of resources used and the amounts of waste discharged by making effective use of resources and promoting resource circulation, not only within the Group but also throughout the entire supply chain, including suppliers. Specifically, aiming to be an enterprise that reduces waste, ideally generating no waste, and recycles waste as resources, we strive to reduce the amounts of waste discharged while at the same time reducing the amount of waste that is not recycled but discharged by means of landfill or simple incineration. We will promote activities both before and after discharge of waste.

Targets NITORI Group Green Vision 2050

In the “Promotion of Circular Business,” we aim to achieve 100% product development based on the premise of resource recycling, while maintaining “Offering the Unexpected” price and quality that anyone can easily afford. We also aim to reduce waste emissions by 50% or more by recycling 100% of the products collected from our customers, and by sorting waste before it is discharged and reusing it as a resource. Even for items that must be disposed of, we aim to achieve a 100% recycling rate by not sending them to landfill. The expertise we have accumulated in this way will be used again in the “manufacturing” stage to develop products that are recyclable. In this way, we aim to establish a recycling system that can only be realized by the Nitori Group. We also aim to switch 100% of our product packaging to materials with reduced environmental impact while maintaining the quality of “Offering the Unexpected.”

Achievements

Measures

- Examples of Resource circulation initiatives[

380KB]

380KB] - The recycling

collection of curtains(Japanese language only)

- The recycling collection

of down feather quilts(Japanese language only)

Respose to Climate Change

Policy

NITORI Group recognizes a range of risks caused by the impact of climate change, and by taking advantage of our unique business model, we pursue total optimization of all stages of our supply chain to improve efficiency, thereby reducing greenhouse gas emissions and mitigating the impact of climate change. In order to further effectively address climate change, which is an important management issue, NITORI Group has endorsed the recommendations of the TCFD (Task Force on Climate-related Financial Disclosure) and is participating in the TCFD Consortium, a forum for discussion among companies and financial institutions that support the TCFD. We also recognize the finite nature of energy essential to our business activities, and by leveraging our unique business model, we will work to reduce our use of energy through more efficient energy use throughout our supply chain.

Disclosure based on TCFD Recommendations (Japanese language only)

Targets NITORI Group Green Vision 2050

We aim to reduce Scope 1+2 greenhouse gas emissions (including overseas sites) as follows.

- Fiscal 2030: 50%reduction compared with fiscal 2013 (emissions per 100 million yen of net sales)

- Fiscal 2050: Become carbon neutral (net zero emissions)

Going forward, we will promote the development of products with environmentally friendly functions, including reduction of greenhouse gas emissions during the customer's use of the product, and initiatives for waste reduction and recycling. We will also consider disclosing information on reductions of Scope 3 greenhouse gas emissions.

Achievements

Measures

To achieve the above goals, the Nitori Group is pursuing multiple measures. These include the use of

renewable energy sources, the replacement of facilities with energy-efficient electric and gas facilities, and

the use of building methods and materials with high thermal insulation properties. In addition, to promote

capital investment that leads to the reduction of greenhouse gas emissions, “Internal Carbon Pricing (ICP)”

was introduced in FY2023, and investment decisions are made based on the expected future carbon costs (carbon

tax, emissions trading, etc.).

Regarding the use of renewable energy, we have begun operating solar power

generation systems at some Nitori stores. Stores equipped with solar panels generate more electricity than

they use in their own stores, and the surplus power is supplied to other Nitori Group stores in a Group’s

unique circular system. We plan to gradually expand this initiative to include distribution bases. In

addition, we will gradually build charging infrastructure for electric vehicles powered by virtually 100%

renewable energy at approximately 300 Nitori and Shimachu stores in our group, thereby contributing to

improved convenience for customers and reduction of greenhouse gas emissions.

- Details: Press Releases > Expansion of EV Charging Infrastructure at Domestic Stores

(as of July 2023, Japanese language only)

- Details: Press Release: Realization of a Renewable Energy Cycle Based on Solar Power

Generation and Use of Surplus Electricity (as of June 2024, Japanese language only)

Publication of statutory reports on global warming measures

- Tokyo Metropolitan Government: Global Warming

Countermeasures Report(Japanese language only)[

245KB]

245KB] - Saitama Prefecture: Global Warming Countermeasures

Report(Japanese language only)[

1.31MB]

1.31MB] - City of Yokohama: Global Warming Countermeasures

Report(Japanese language only)[

327KB]

327KB]

Reduction of the Amount of Water Used/Prevention of Pollution

Policy on reduction of the amount of water used

Recognizing the finite nature of water resources and the risk that water shortages pose to our business, we will strive to reduce the amount of water used throughout our supply chain.

Policy on prevention of pollution

Recognizing the risk that air and water pollution poses to our business, we will safely manage chemical substances potentially hazardous to the environment throughout our supply chain.

Examples of Reduction of the Amount of Water

Used/Prevention of Pollution initiatives[![]() 274KB]

274KB]